Machine Features

Brief introduction of Coated Peanut Production Line:

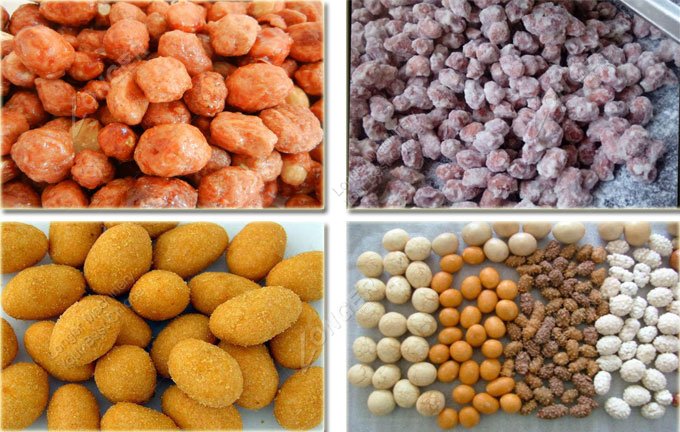

The peanut sugar coating machine line is the latest production line our company produced. The machine can is widely used for peanuts, sunflower seed,almond and cashew nuts, which can coat peanut with sugar, flour, honey and other spices. The honey coated peanut production line consists of peanut roasting machine,peanut peeling machine, peanut coating machine, particle swing roasting machine,flavoring machine,cooling machine and granule packing machine.

Technological Process of Flour Coated Peanut Production Line:

Material---Roasting---Peeling---Coating--Baking--Flavoring---Packing

Introduction of main Machine:

1.Peanut roasting machine

This peanut roasting machine is mainly used for drying and baking peanut, beans, coffee beans, melon seeds and other nuts. The machine adopts the design of rotating drum, using the principle of heat conduction and heat radiation, the baked products taste pure. The peanut roasting machine has the advantages of energy-saving, safety, health, convenience and easy operation.

2.Peanut peeling machine

We have two models for dry/wet peeling machines, especially for peanut and almond skins. Both of the two peeling machines has simple operation and simple maintenance, and the stripping rate up to 96%. The drying method uses the pneumatic principle of peanut peeling machine, it can automatically remove the red skin of peanut, without any damage. The wet peanut peeling machine has reliable quality, low damage rate and good performance. Peanuts need to be baked or dried before being put into a peeling machine. The peeling machine can remove the skin of chickpea off easily and gently like human hand.

3.Peanut Coating Machine

Peanut coating machines are widely used in food machinery and medicine machinery. The peanut coating machine is equipped with a 30 degree sugar coated pot, which can place heating equipment (such as electricity or gas) under the pot. It is made of stainless steel, which is clean and durable.

The machine can be matched with an electric heat blower and has an air outlet that reaches into the pan for heating or cooling, adjustable.

The machine has simple structure, convenient operation and smooth surface. It saves parts and is easy to maintain. This machine is an ideal machine for peanut processing.

Advantages of Coated Peanut Production Line:

1.The whole flour honey coated peanut production line has realized automatic process production, saving a lot of human resources and reducing production cost, which can be customized according to customers' needs.

2.The peanut sugar coating machine is an advanced, practical and reasonably priced new generation of products.

3.The peanut sugar coating machine is made of stainless materials, which can meet international standards.

Our service for Flour Honey Coated Peanut Production Line:

1.We will reply to customers' questions about our machines within 24 hours by email/phone

2.We will make the best design according to the requirements and environment of customers

3.We are responsible for installation, debugging and training and provide technical guidance for common problems

4.In addition to rapidly wearing parts, the whole machine is guaranteed for one year. If there is any problem with the machine, we will provide 24-hour technical support via email/phone.

If you have demand for the coated peanut production line, you can contact us.

Machine Technical Data

| Name | Parameter |

|

Peanut Roasting machine (Gas heating) |

Temperature: Normal Capacity: 500-650kg/h Power: 5.5kw/380V /50HZ Dimension: 5.5*3*1.7 m |

| Peanut peeler |

Peeling performance: 96% Voltage: 380V/220V/50hz Capacity: 500kg/h |

| Coating machine |

Capacity: 120kg/h power: 0.75kw |

| Particle swing roasting machine |

Power:0.75kw Electrical heating power:20kw Capacity: 150-200kg/h Voltage:380V/50hz |

| Flavoring machine |

Power:0.75kw Capacity: 250kg/h |

| Cooling machine |

Power:7.5kw Capacity:1-2T/h Dimension: 6*0.8*1.2m |

| Granule Packing Machine |

Power:2.5KW/220V Measure Range:10-120g/bag. Bag Size:L:50-160 W: 30-130 Capacity:30-60 bags/minutes |

Automatic Coated Peanut Production Line With Sugar/Flour/Honey

Automatic Coated Peanut Production Line With Sugar/Flour/Honey