Machine Features

Introduction of Buckwheat Processing Equipment:

This set of Buckwheat Shelling Machine consists of two machines: Buckwheat Grading Machine and Buckwheat Shelling Machine. It is recognized to be one of the most optimum equipment for buckwheat hulling and separating in the world.

This set of Buckwheat Shelling Machine consists of two machines: Buckwheat Grading Machine and Buckwheat Shelling Machine. It is recognized to be one of the most optimum equipment for buckwheat hulling and separating in the world.

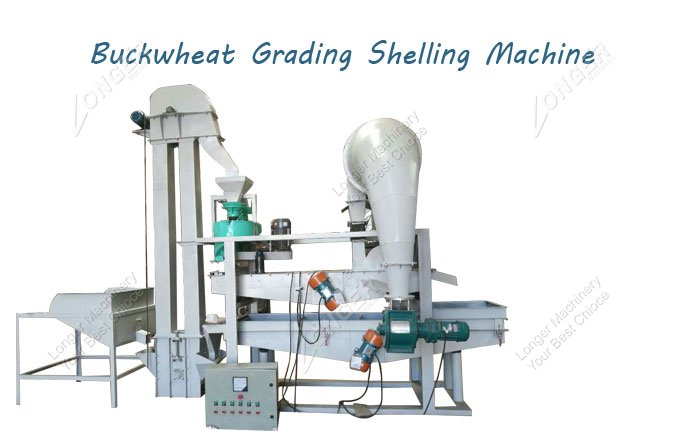

Working principle of Buckwheat Grading Shelling Machine/Processing Equipment:

Raw materials (buckwheat) is fed into the input hopper and through the spiral elevator to cleaner, where the raw material is well pre-cleaned before going for dehulling, and then clean oats into the bucket elevator in advance, and then elevated bucket elevator to sheller for shell. The mixture of shells and seeds will fall on the husk-seed-grain separator after the husk is removed to separate the shell from the seed and kernels. Through the cyclone, all the shells are discharged by the shell unloader. After the shell is removed, the seeds and grains are transported to the seed-grain separator to separate the seeds from the grains. After separation, the kernel will move forward to the separator separation again, but not shelled seed move back to the bucket elevator, then enter the sheller to shell, then into the shell - nuclear separator separation from seed shells and benevolence. Materials has already entered the separator for separating will be the first to be removed again small and broken shell, and then the front of the fine separation after work will be the kernel ejection and collection box, and unhulled seeds and small amounts of the kernel will move back to the entrance of the material flow device and then again into the separator to separate again.

Advantages of Buckwheat Processing Equipment:

1.This buckwheat shelling machine is well designed with low material loss and maintenance cost

2.After the improvement of the technology, the efficiency of the dehulling rate of the machine is obviously improved and the crushing rate is decreased.

3.The price of the set of machine is factory price, which sells with good quality at a cheap price.

4.It adopts negative pressure suction to collect the pumpkin shells.

5.The machine uses wet method de-hulling process, which promote the working efficiency.

Our service for Buckwheat Processing Equipment:

1.Consulting service: If the user encounters any problems during the use, he can call the company for technical support.

2.For products under warranty period, if there are quality problems, the company is responsible for warranty service.

3.We have our own factory, and our customers can conduct on-the-spot inspections of our factories according to actual needs.

If you have any questions about our buckwheat processing equipment, you can contact us.

This is our buckwheat shelling machine working video:

Machine Technical Data

| Model | LG-PD50 |

| Packing Range | 15-50KG ajdustable |

| Precision | ±0.2% |

| Packing Speed | 300-600 bags/hour |

| Voltage | 380V |

| Main Motor Power | 0.37kw |

| Weight | 200KG |

| Dimension | 900*550*2280mm(L*W*H) |

Buckwheat Grading Shelling Machine | Processing Equipment

Buckwheat Grading Shelling Machine | Processing Equipment